Let me introduce the components of Heunghwa Injection Machine

Characteristics of SCREW

As a standard specification, the recently developed alloy-resistant bimetal cylinder is resistant to corrosion, provides stable engineering plastic molding, and prolongs the life of the heating cylinder

It supplies dedicated screws suitable for various resins, such as unimelt screws for high kneading, internal corrosion suitable for resins containing glass fiber, and abrasion-resistant screws

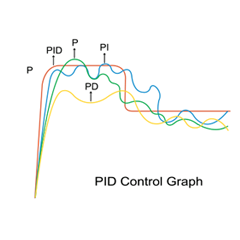

In response to a temperature change, overshooting is reduced to realize precise temperature control, and a precise SSR (non-contact relay) used for nozzle temperature control improves stability during molding and prolongs the life of the control circuit

Characteristics of hybrid

HYBRID PUMP

SERVO MOTOR

& Amp System

Characteristics of CONTROLLER

01 Operation Status

02 Injection

03 Ejector

04 Temperature setting

05 Clamping Setup

06 Nozzle & Others